Successfully in use

Why does Daniel Burkhard seal ready meals with a sustainable protective barrier at his bakery?

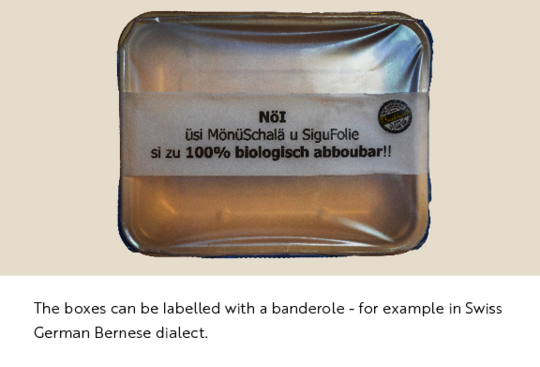

Bäckerei Burkhard is a traditional bakery with several branches in Switzerland. Besides baked goods and patisserie products, the company offers ready meals that are prepared fresh every day and sold in sealed trays. Previously they had used a variety of trays, films and lids. The introduction of naturesse’s MAP-capable and completely biodegradable packaging solution has simplified this process, and the food stays fresh for longer.

Compelling advantages:

- Better shelf life for products and less food waste: the extra barrier layer in the tray

and the sealing film protects the food and prolongs its freshness. - Simplified ordering process: fewer different items are required, making purchasing easier.

- Optimised stock management: by reducing the number of packaging components

required, less space is needed. - Sustainability as a sales argument: the compostable full solution offers added value for eco-conscious customers.

- Efficiency in production: sealing the ready meal trays has become easier, which optimises the work process.

The interview with Daniel Burkhard

We spoke to the owner of Bäckerei Burkhard about the changeover and the advantages of the new packaging solution.

Why did you decide to make the switch? What were the challenges?

We weren’t actually having any real problems, but we’ve been working with regular partners for many years and rely on their suggestions. When Pacovis told us about the idea behind the new MAP sealing concept, we were interested right away. The collaboration with Pacovis is very close and we know we won’t be offered half-measures. Sustainability is an important topic, but it often fails when it comes to the implementation. With this solution, we have found a practicable alternative to the previous concept, and one that really works.

Did you have to adapt your machines for the new concept?

No, we had already recently renewed the sealing machine to optimise the packaging process. That made the switch extremely easy for us.

What are the advantages of the new packaging system?

The biggest improvement is the simplification of our packaging process. Instead of different trays, films and lids, we now only use a single tray, a sealing film and a lid. This saves storage space and makes ordering easier. We also benefit from better purchase prices due to the larger order quantities. The new packaging is not only sustainable, but the MAP barrier keeps the food fresh and protected for longer.

How do customers react to the sustainable packaging?

Most customers are very positive about it. We have put a sign in our display case and our staff explain the advantages of compostable trays and films to customers. Of course there are always a few sceptical voices, but overall the changes have been well received.

Were there any initial challenges?

Yes, there were minor technical difficulties with the sealing film to begin with, but Pacovis supported us closely. Christian, our Pacovis contact, was on the spot right away and solved the problem quickly. That’s what I call proper collaboration!

What about reusable alternatives?

We discussed the issue of reusable trays extensively, but ultimately decided that it was not workable for our customers. Most of them simply don’t have the time or opportunity to return trays. We’re out in the country here and it’s often labourers who buy ready meals for their lunch. They don’t have the same opportunities to bring their trays back as people in the city or people with a fixed workplace, for example. With compostable single-use packaging, we have found a sustainable solution that is also economically viable and is consistent with our customer base.

What impact does the new concept have on production?

We haven’t necessarily become faster, but we are working more efficiently. We produce two ready meals a day for lunch and, thanks to the new packaging solution, we no longer have any waste at lunchtime. Anything that’s left over is kept and sold the next day. This reduces losses and maximises our efficiency.

What makes our MAP solution unique?

- Additional barrier layer in the tray and in the sealing film, making the product gas-flushable

- Low permeability of water vapour and oxygen

- Shelf life of the ready meals up to 10 days thanks to integrated barrier = less food waste

- Bio sealing film with very good peel and seal properties

- Made from a fast-growing renewable raw material (tray consists of sugar cane fibres which otherwise remains unused)

- Biodegradable according to DIN EN 13432 and climate-friendly

- Guaranteed food-safe

- Approved quality tested according to EU standards

- Available in the colours white and nature